I lead a team dedicated to Reliability Consulting—a mission we take seriously. Our goal? Empowering your facility with the knowledge needed to make precise decisions at critical junctures.

Here’s how we achieve that:

- Cutting-Edge Technologies:

- We harness a suite of advanced technologies, including vibration analysis, reciprocating compressor diagnostics, ultrasound, thermography, and alignment. These tools provide unparalleled insights into your equipment’s health.

- Our PDM (Predictive Maintenance) data collectors consolidate these capabilities into a single unit, streamlining your monitoring process.

- Precision Training:

- ISO 18436-2 Cat 1-3 vibration analysis training is our forte. Whether you’re an individual seeking professional development or a team aiming for excellence, we’ve got you covered.

- Visit - Zenco Vibration Experts (zencovibrations.com) for a comprehensive list of public courses. Use discount code “3DB” for extra savings.

- Specialized Analyses:

- Beyond vibration, we delve into API 618 pulsation and acoustics analysis, torsional analysis, pipe stress assessment, and dynamic (FEA) analysis. Our expertise spans the spectrum.

- Your Efficiency, Our Priority:

- We understand that an efficiently running facility directly impacts your bottom line. That’s why we’re committed to providing accurate, actionable information.

- Informed decisions are your ticket to success, and we’re here to ensure you hold that ticket firmly.

Remember, we’re not just consultants; we’re partners invested in your success. Let’s elevate reliability together.

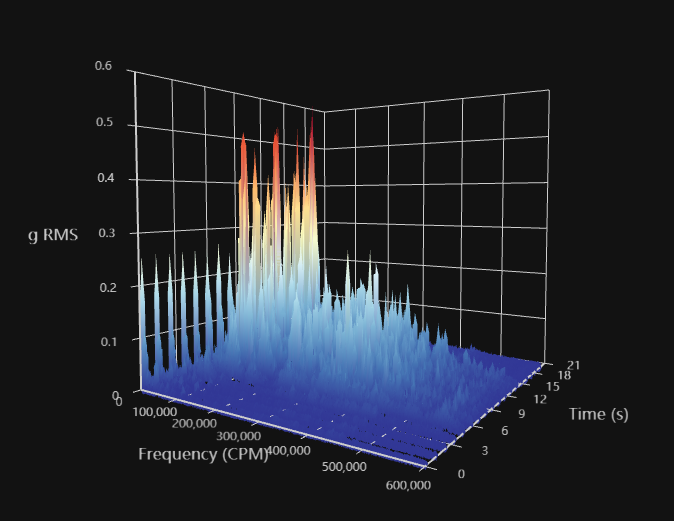

Vibration Analysis Services

Vibration analysis is like deciphering a secret language spoken by machinery—a language that reveals crucial insights. It’s not magic; it’s the art of listening to what equipment whispers through its vibrations. 🛠️

Much like a skilled doctor interpreting an EKG to understand the heart’s rhythm, we “listen” to the heartbeat of your machinery. Each vibration pattern tells a story: misalignments, imbalances, bearing wear, and more. It’s a fascinating dance between physics and diagnostics.

And you’re right—the fault conditions we can uncover using vibration analysis are astonishing. From subtle imbalances to impending failures, this technology is our stethoscope for industrial health. So, let’s keep decoding those vibrations and ensuring smooth operations!

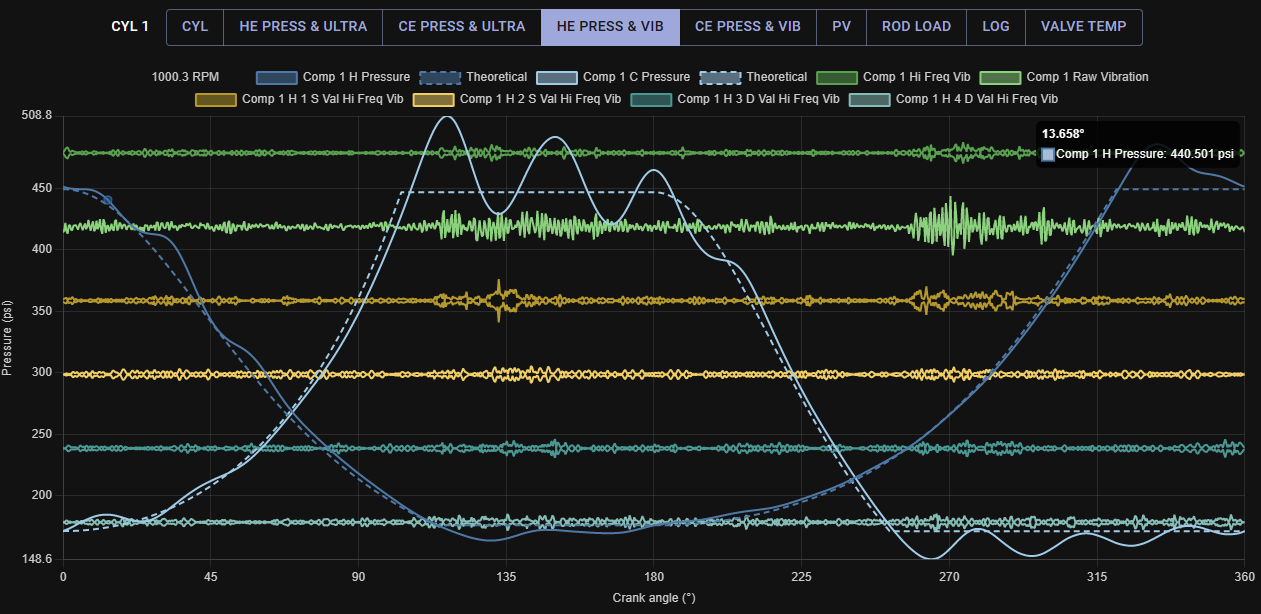

Recip Engine/Compressor Performance Analysis

Reciprocating engine and compressor performance analysis represents the pinnacle of diagnostic scrutiny for these vital components. During this meticulous process, we gather data from various sources: vibrations, pressure measurements, ultrasound, ignition signals, and infrared scans—all meticulously synchronized to the crankshaft’s beat. What emerges is a comprehensive portrait of the machine’s health.

We delve deep, uncovering mechanical secrets: valve and ring issues, cylinder anomalies, bearing play, and even structural irregularities. But that’s not all! Our discerning eye extends beyond the metal and into the gas passages. We scrutinize the flow through compressor cylinders, bottles, and piping, seeking out inefficiencies and losses.

In essence, it’s like peering into the very soul of these mechanical marvels, revealing their strengths and vulnerabilities alike.

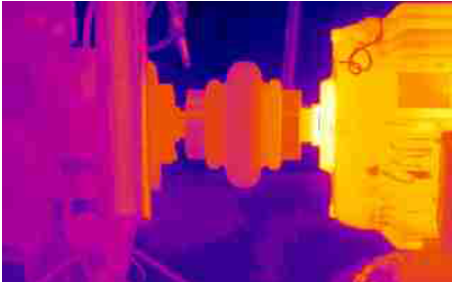

Thermography

Our visual diagnostic tool (thermography)—like an artist’s brush—reveals both mechanical and electrical secrets. Bearings strain, misalignments confess, and resistance glows. It even whispers of leaking valves and vessel build-up. In this pixelated atelier, we decode faults into actionable wisdom.

Vibration Analysis Training and Certification

Online or On-site vibration analysis training and certification in accordance with ISO-18436-2 is available for Categories I, II and III. Training is available in English or Spanish. Virtual live courses provide the easiest and most affordable way to get certified but Alan is available to travel to your site and teach you in person. Get certified Cat 1, Cat 2 or Cat 3 and watch your career take off!